Are Wearable Electronics the Next Recycling Nightmare?

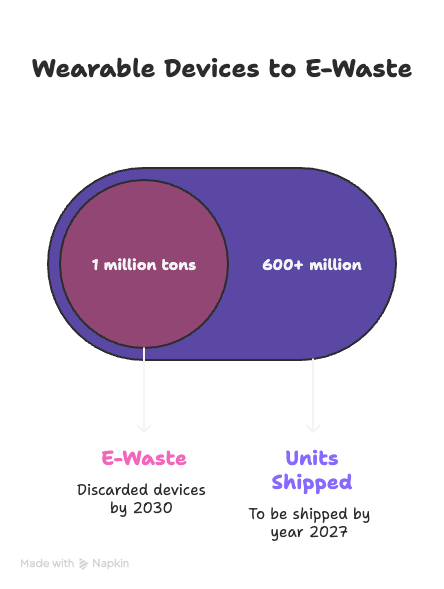

Walk down any busy street and you’ll see them everywhere, smartwatches on wrists, wireless earbuds tucked in ears, fitness trackers counting steps, AR glasses starting to creep into the mainstream. Wearables are no longer niche gadgets. They’ve become fashion statements, health monitors, productivity tools, even medical devices. Global shipments of wearables are projected to exceed 600 million units annually within the next few years, fueled by consumer demand for constant connectivity and companies racing to build ecosystems of devices that lock in users.

But here’s the thing: while wearables feel sleek, futuristic, and light, they hide a dark reality. They may represent one of the most difficult categories of electronic waste to recycle and right now, very few players in the recycling ecosystem are prepared to handle them

Small Size, Big Problem

E-Waste includes discarded electronic devices like smartphones, laptops, TVs, and appliances The first challenge is scale, not in volume, but in physical size. Wearables are incredibly compact by design. Engineers pack batteries, sensors, chips, antennas, and displays into devices sometimes smaller than a coin. This miniaturization is brilliant for consumers, but it’s a nightmare for recyclers.

Why? Because the economics of recycling rely on recoverable material. A laptop, for example, may contain tens of grams of valuable metals like copper, gold, or palladium. A smartwatch contains only a fraction of that. The effort required to safely extract those materials, dismantling, shredding, chemical separation often outweighs the market value of what can be recovered.

In other words, the smaller the gadget, the harder it is to justify recycling it with today’s systems.

Batteries Everywhere

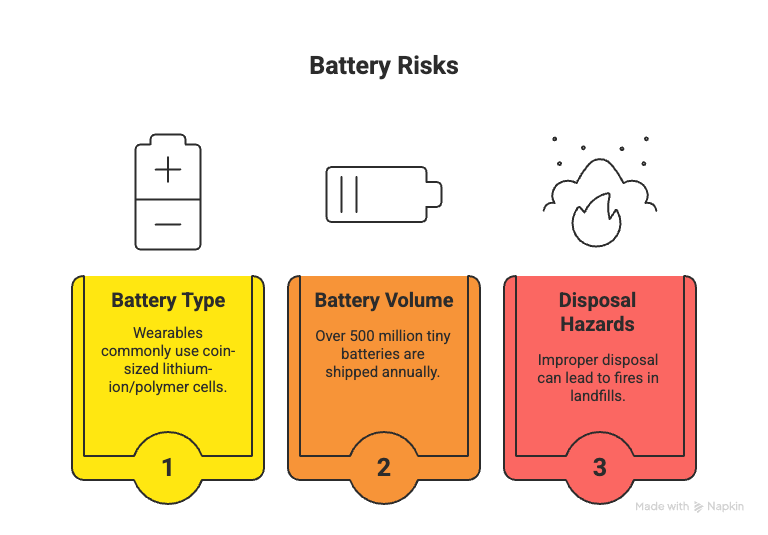

Then there’s the battery problem. Most wearables use tiny lithium-ion or lithium-polymer cells, often glued directly into the casing. Removing them is tricky, sometimes impossible without destroying the device. From a recycling perspective, this is dangerous. Puncture one of these micro-batteries and you risk fire or toxic leakage.

Multiply that by hundreds of millions of units, and you’re looking at a very real safety and logistical challenge for recyclers. It’s one thing to handle large EV batteries with structured processes. It’s another to process a mountain of coin-sized batteries glued inside plastic and metal shells.

Disposable by Design

Another uncomfortable truth: wearables are not built to last. The average smartwatch or fitness tracker is obsolete within 2–3 years. Batteries degrade, new models launch, operating systems stop supporting older devices. Earbuds are even worse, once the tiny batteries lose capacity, replacement is rarely an option. Consumers simply throw them away and buy the latest model.

This “disposable by design” trend makes wearables one of the fastest-growing contributors to the short-lifespan electronics crisis. The irony is painful: companies market wearables as tools for healthier lifestyles, yet their environmental footprint tells a different story.

Hidden Treasure Inside

And yet, these devices aren’t worthless. Inside every wearable are rare earth elements and critical minerals, neodymium in speakers and haptic motors, cobalt and lithium in batteries, tantalum in capacitors, indium tin oxide in displays. Each gram matters.

To put this in context: the International Telecommunication Union estimates that a ton of discarded smartphones can yield more gold than a ton of ore mined from the earth. Wearables, though smaller, are part of the same story. Left unrecovered, they represent a slow leak of critical materials that the clean energy transition desperately needs.

This is why wearable e-waste isn’t just an annoyance; it’s a strategic issue. As demand for rare earths, lithium, and cobalt soars for EVs, wind turbines, and solar panels, letting millions of wearables rot in drawers or end up in landfills is simply unsustainable.

The Recycling Roadblocks

So, why aren’t we tackling this already? Several reasons:

- Lack of scalable processes: Current recycling lines aren’t optimized for devices this small. Manual dismantling is too costly; automated shredding often destroys the very materials we want to save.

- Economics: The market value of the metals inside a smartwatch may not even cover the cost of safe collection and processing. Without subsidies or extended producer responsibility (EPR) programs, recyclers lose money.

- Consumer behavior: Most wearables never make it to recycling facilities. They end up forgotten in drawers, tossed in household trash, or left in landfills. Collection is the Achilles’ heel of the circular economy.

- Design barriers: Devices glued shut, with non-replaceable batteries and proprietary components, block disassembly and recovery.

Solutions on the Horizon

Here’s the good news: the conversation is shifting. Innovators, policymakers, and recyclers are starting to recognise the wearable e-waste problem and a few solutions are emerging.

- Consumer Incentives: Trade-in credits, discounts on new models, or even deposit-return schemes for small electronics could improve collection rates.

- Design for Disassembly: Some companies are exploring modular wearables where batteries and components can be replaced. It’s not mainstream yet, but pressure is mounting as right-to-repair legislation gains traction.

- Micro-Recycling Technology: Labs are developing precision recycling methods, micro-shredders, advanced chemical separation, even robotic disassembly for small devices. The challenge is scaling these beyond pilot projects.

- Producer Take-Back Programs: Apple’s Daisy robot for iPhone disassembly gets attention, but what about AirPods or watches? Companies may soon be required to extend take-back to all devices, including wearables.

- Policy Pushes: The EU is leading with stricter e-waste directives, and wearables could be the next category to face regulation. Extended Producer Responsibility (EPR) laws will force manufacturers to bear recycling costs.

The Bigger Picture

PrAt first glance, wearable e-waste might look like a niche issue. After all, a smartwatch is tiny compared to an EV battery. But scale changes the math. Hundreds of millions of small devices, discarded every few years, create a waste stream that is enormous in aggregate.

What this really means is that the wearables boom is stress-testing the entire recycling ecosystem. If we can’t figure out how to efficiently recover materials from small, complex devices, how can we claim we’re ready for the circular economy?

The stakes go beyond waste management. They tie directly into supply chain resilience, climate goals, and the ethics of resource extraction. Every unrecycled wearable is a lost opportunity to reduce mining, conserve rare earths, and close the loop.

Closing Thought

So, are wearable electronics the next recycling nightmare? Yes, unless we act now. It’s a nightmare in the making, but also an opportunity. An opportunity to demand better design from manufacturers, to build smarter recycling systems, and to rethink how we as consumers treat the devices strapped to our wrists and tucked in our ears.

If we get it right, wearables could become a case study in how to build circularity into even the smallest of technologies. If we ignore it, we’ll be left with mountains of tiny, toxic gadgets piling up faster than we can manage.

The clock is ticking, quite literally, on millions of wrists around the world.

You can find all the useful information you need on the Vavada mirror. Find out why players switch to the official Vavada website via the mirror, and discover the benefits: similar registration and login processes, bonuses, promo codes