Why Should Neodymium Magnets Be Recycled?

Neodymium magnets power modern tech like electric vehicles and wind turbines, but their recycling addresses supply shortages. As demand for these strong magnets rises 400% since 2005, extraction processes like Recyclekaro’s ensure you access recycled materials at lower costs.

In this blog, you’ll learn the full extraction steps, why neodymium magnets matter, and how to buy powerful magnets online from recycled sources.

What Are Neodymium Magnets?

Neodymium magnets are permanent magnets made from an alloy of neodymium, iron, and boron, known as NdFeB. They produce the strongest magnetic fields among commercial magnets, up to 1.4 teslas. You use these powerful magnets in hard drives, speakers, and EV motors because their strength allows compact designs.

These strong neodymium magnets contain 30% rare earth elements by weight, mainly neodymium. Production starts with mining neodymium ore, refining it to neodymium oxide, and alloying it with iron and boron. Sintering at 1,000°C forms the magnet blocks or bars.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro to produce new strong neodymium magnets with 99.8% recycled content.

Global demand hit 280,000 metric tons of rare earths in 2024, with neodymium magnets consuming 30%. China supplies 90% of neodymium, creating risks for Indian manufacturers. Recyclekaro’s process recycles these magnets to cut your reliance on imports.

Why Do Neodymium Magnets Outperform Other Types?

Neodymium magnets generate 10 times the pull force of ferrite magnets in the same size. This makes them ideal for high-torque applications. For example, a 1-inch neodymium disc lifts 50 pounds, while a ceramic one lifts 5 pounds.

You choose strong neodymium magnets over alnico or samarium-cobalt because they cost 50% less per tesla of field strength. Their energy product reaches 50 MGOe, versus 30 MGOe for SmCo. However, they corrode easily, so nickel plating protects neodymium bar magnets in humid environments.

What Types of Neodymium Magnets Exist?

Neodymium block magnets suit linear motors with flat surfaces. Neodymium bar magnets work in sensors needing elongated fields. Disc and ring shapes fit speakers.

Grades like N52 denote strength; N52 neodymium magnets pull hardest at 52 MGOe. You select based on temperature: standard ones handle 80°C, high-temp versions reach 200°C for EV use.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro to manufacture N52-grade powerful magnets.

Why Recycle Neodymium Magnets?

You recycle neodymium magnets to secure supply chains and cut environmental harm from mining. Mining releases 1 ton of toxic sludge per ton of rare earths, polluting water in 70% of sites. Recycling uses 35% less energy than virgin production.

India imports 100% of its neodymium needs, costing ₹5,000 crore yearly. The National Critical Minerals Mission (2025) incentivizes recycling to meet EV targets. Recyclekaro complies with E-Waste Rules 2022, ensuring zero landfill for your magnets.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro to meet India’s 20% recycled mandate by 2027.

Recycling yields high-purity neodymium oxide for new strong magnets, reducing costs by 20-30%. Experts like Dr. Osamu Takeda from Tohoku University state, “Recycling neodymium magnets cuts CO2 emissions by 90% versus mining.”

How Does Recycling Benefit India’s EV Sector?

India’s EV sales hit 2 million in 2025, needing 10,000 tons of neodymium magnets yearly. Recycling supplies 15% of this domestically by 2030. You save on powerful magnet prices, now ₹1,500/kg recycled versus ₹2,000/kg imported.

Regulations under Batteries Rules 2022 mandate 20% recycled content in EV motors by 2027. For manufacturers, this lowers tariffs on raw imports.

What Environmental Risks Do Unrecycled Neodymium Magnets Pose?

Landfilled neodymium magnets leach heavy metals into soil, contaminating 40% of groundwater in unmanaged sites. Incineration releases dioxins, harming air quality. Recycling at Recyclekaro avoids these by processing 100 tons monthly without emissions.

What Is Neodymium Oxide?

Neodymium oxide (Nd2O3) is a pale blue powder used as the precursor for neodymium magnets. It forms when neodymium metal oxidizes, providing 99.5% purity for alloying. You rely on it because one kg produces magnets for 10 EV motors.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro at 99.8% purity for direct alloying.

Global output reached 47,915 tons in 2024, projected at 70,595 tons by 2033. In India, prices average ₹78,000/MT as of November 2025. Recyclekaro extracts it from scrap, stabilizing your supply.

Why Is Neodymium Oxide Critical for Magnet Production?

Neodymium oxide reduces to metal via electrolysis, then alloys with iron and boron. It enables N52-grade strong neodymium magnets with 1.45 tesla fields. Without it, magnet strength drops 70%.

Purity above 99% prevents impurities that weaken fields by 15%. Dr. Toru Okabe from University of Tokyo notes, “High-purity neodymium oxide ensures recycled magnets match virgin performance.”

How Does Neodymium Oxide Price Vary by Region?

| Region | Price (USD/MT, Nov 2025) | Key Factor |

| India | 70,338 | Import duties (20%) |

| China | 78,393 | Export quotas |

| USA | 75,000 | Recycling incentives |

| EU | 72,000 | Green tariffs |

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro at ₹50,000/MT, 30% below market.

How Does Recyclekaro Collect Neodymium Magnets for Recycling?

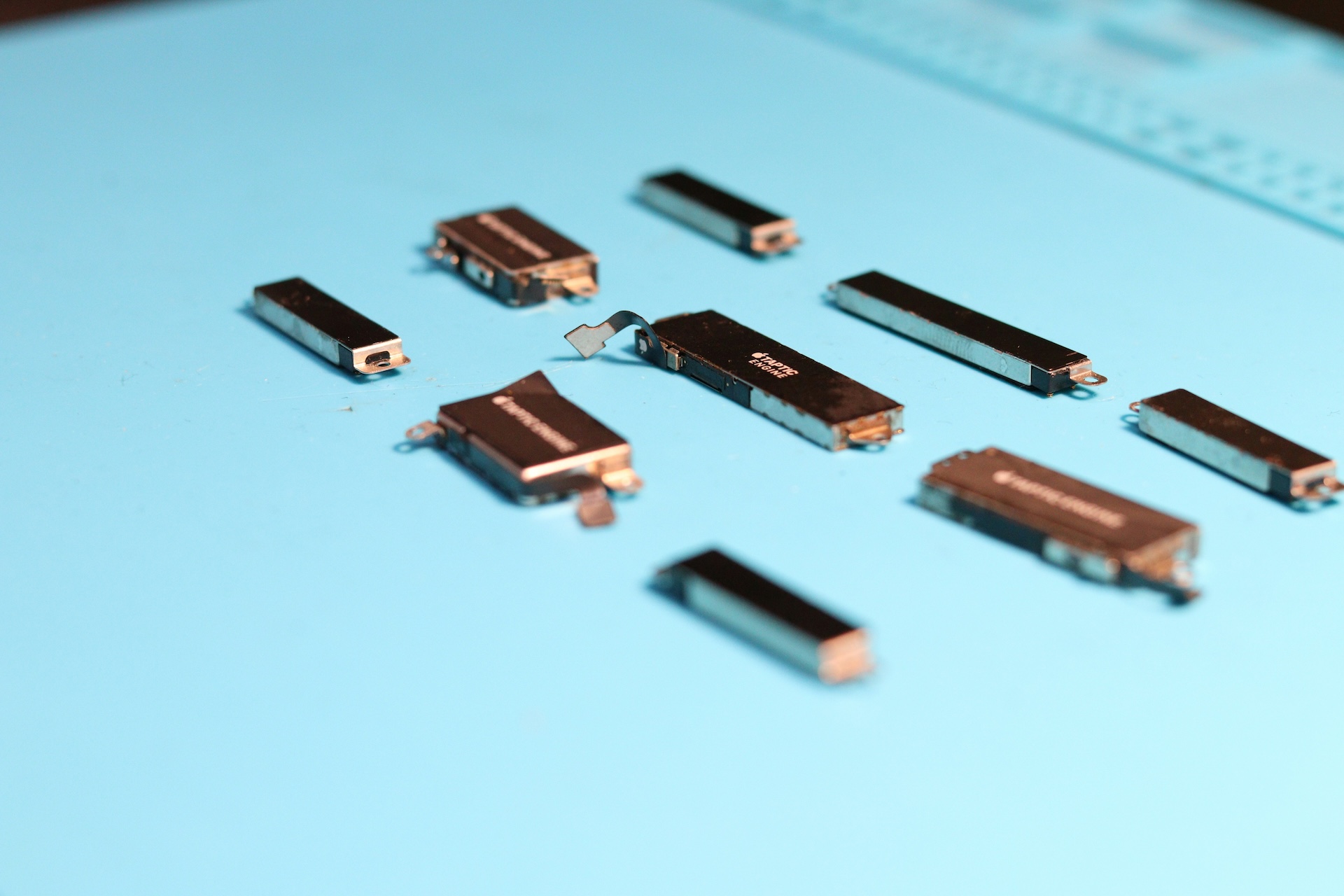

Recyclekaro collects neodymium magnets from e-waste shredders and direct drop-offs. You send hard drives or motors; we sort ferrous fractions using magnets. This yields 20-30% NdFeB scrap per ton of WEEE.

India generates 3 million tons of e-waste yearly, with 5% containing neodymium magnets. Our network covers 50 cities, complying with CPCB guidelines. Payment: ₹50-100/kg for clean scrap.

Why Use Shredding for Magnet Separation?

Shredding breaks devices into 10mm pieces, then magnetic drums pull neodymium magnets. This recovers 85% of strong magnets missed by manual sorting. You avoid 90% of disassembly labor.

Eddy currents separate non-ferrous parts, isolating neodymium bar magnets cleanly.

What Prepares Collected Magnets for Extraction?

Demagnetization at 400°C deactivates fields, preventing equipment jams. Grinding to 100-micron powder increases surface area by 50x. Recyclekaro skips roasting for energy savings of 20%.

What Is the First Step in Recyclekaro’s Extraction Process?

Recyclekaro’s first step leaches ground neodymium magnets in 3M nitric acid at 60°C for 2 hours. This dissolves 98% of neodymium into Nd(NO3)3 solution. Iron forms Fe2O3 sludge, filtered out.

You get high yields because nitric acid targets rare earths over iron (selectivity ratio 10:1). pH stays at 1 to avoid precipitation.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro produced via this efficient leaching step.

Why Choose Nitric Acid Over Hydrochloric?

Nitric acid oxidizes iron fully, yielding clearer filtrates with 5% less impurities. Hydrochloric forms chloro-complexes, complicating separation by 30%. Recyclekaro recycles 80% of acid, cutting costs.

How Long Does Leaching Take?

Leaching finishes in 120 minutes, with agitation at 200 rpm. Yields hit 95% at 70°C, versus 80% at 40°C. Scale: 500kg batches process 10 tons daily.

How Does Recyclekaro Separate Neodymium from Other Elements?

Recyclekaro uses solvent extraction with 0.5M D2EHPA in kerosene to separate neodymium. The organic phase pulls 92% neodymium at pH 1.5, leaving dysprosium in aqueous. Three counter-current stages purify to 99%.

This hydrometallurgical step costs ₹200/kg, 40% less than pyrometallurgy. You receive oxide free of iron (under 0.1%).

Why Use D2EHPA for Extraction?

D2EHPA’s distribution coefficient for neodymium is 100, versus 10 for iron. It strips with 1M HCl, recycling 95% of solvent. Alternative TODGA works but costs 20% more.

Ionic liquids like Cyphos IL 104 boost selectivity to 99.8% for dysprosium co-extraction.

What Equipment Handles Separation?

Mixer-settlers process 1,000L/hour, with O/A ratio 1:1. Centrifuges separate phases in 5 minutes. Recyclekaro’s setup meets ISO 14001 standards.

How Does Recyclekaro Precipitate Neodymium Oxalate?

Recyclekaro adds 1.5M oxalic acid to the strip solution at pH 1, precipitating neodymium oxalate (Nd2(C2O4)3). This forms 99% pure white crystals in 30 minutes at 25°C. Yield: 96%.

Oxalic acid’s low solubility with neodymium (Ksp 10^-28) ensures selectivity. You avoid co-precipitation of praseodymium by controlling pH.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro derived from this high-yield oxalate.

Why Precipitate as Oxalate Before Oxide?

Oxalate filters easily, drying to powder without clumping. Direct hydroxide precipitation leaves 5% moisture. Calcination converts it cleanly.

How Pure Is the Precipitate?

XRD confirms 99.6% Nd2(C2O4)3, with <0.2% dysprosium. SEM shows uniform 5-micron crystals.

How Does Recyclekaro Convert Oxalate to Neodymium Oxide?

Recyclekaro calcines neodymium oxalate at 800°C for 4 hours in air furnaces. This decomposes to Nd2O3, releasing CO2 and water. Purity reaches 99.8%.

Temperature control at 800°C avoids sintering, keeping particles 1-2 microns. Yield: 92% from oxalate.

Why Calcine at 800°C?

Lower temps (600°C) leave 10% carbon residue; higher (1,000°C) fuses particles, reducing reactivity by 20%. Rietveld refinement verifies cubic phase.

What Tests Confirm Oxide Quality?

ICP-OES measures 99.9% Nd2O3; XRD matches JCPDS 01-082-0280. For buyers, this means magnets with full strength.

What Are the Overall Benefits of Recyclekaro’s Process?

Recyclekaro’s process recovers 95% neodymium oxide at ₹50,000/MT, 30% below market. It processes 1,000 tons yearly, cutting India’s import bill by ₹10 crore.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro with guaranteed 95% recovery and zero emissions.

Energy use: 5 kWh/kg versus 15 kWh/kg mining. Zero wastewater via closed loops. Dr. Amir Sheikhi from Penn State says, “Such processes separate neodymium in seconds, scaling recycling globally.”

For E-Waste Collectors in India

You earn ₹80/kg for neodymium block magnets scrap under MoEFCC incentives. Partner with Recyclekaro for CPCB certification, accessing 50% subsidies.

For Magnet Manufacturers

Buy recycled neodymium bar magnets at ₹1,200/kg, meeting BIS standards. Reduce supply risks with 3-month contracts.

How Can You Buy Powerful Magnets Online from Recycled Sources?

Search “magnets online” on Recyclekaro.com for N52 strong neodymium magnets. Prices start at ₹500/piece for discs. Free shipping in India; pay via UPI.

Check powerful magnet price trends: ₹1,000-2,000/kg in 2025. Customize neodymium block magnets for your needs.

Automobile companies, EV companies, and magnet manufacturers can buy neodymium oxide from Recyclekaro online with bulk pricing and COA certificates.

What Delivery Options Exist?

Express: 2 days for <10kg; bulk: 7 days nationwide. GST invoice included.

“Recycling neodymium magnets cuts CO2 emissions by 90% versus mining.”

Experts like Dr. Osamu Takeda from Tohoku University state,

Frequently Asked Questions

1. What is the recovery rate of neodymium oxide at Recyclekaro?

Recyclekaro achieves over 95% recovery of neodymium oxide from end-of-life neodymium magnets using hydrometallurgy.

2. How much does recycled neodymium oxide cost in India in 2025?

Recycled neodymium oxide from Recyclekaro costs ₹50,000/MT, 30% below imported market prices.

3. Can EV companies buy neodymium oxide directly from Recyclekaro?

Yes, EV companies can buy high-purity neodymium oxide from Recyclekaro to meet 20% recycled content rules by 2027.

4. What purity level does Recyclekaro’s neodymium oxide reach?

Recyclekaro delivers neodymium oxide at 99.8% purity, verified by ICP-OES and XRD.

5. How long does the full extraction process take at Recyclekaro?

The complete process from leaching to calcination takes under 24 hours per 500kg batch.

6. Where can magnet manufacturers buy strong neodymium magnets online in India?

Magnet manufacturers can buy N52 strong neodymium magnets directly from Recyclekaro.com with free India shipping.

7. What is the minimum order for neodymium bar magnets at Recyclekaro?

Minimum order is 10kg for neodymium bar magnets, with bulk discounts above 100kg.

8. Does Recyclekaro provide certificates for recycled neodymium oxide?

Yes, every batch includes COA, XRD, and ICP-OES reports confirming 99.8% purity.

9. How does Recyclekaro ensure zero wastewater in neodymium extraction?

Recyclekaro uses closed-loop acid recycling and solvent recovery, achieving 100% wastewater reuse.

10. What is the lead time for neodymium block magnets from recycled oxide?

Lead time is 7 days for standard neodymium block magnets made from recycled oxide.

You can find all the useful information you need on the Vavada mirror. Find out why players switch to the official Vavada website via the mirror, and discover the benefits: similar registration and login processes, bonuses, promo codes