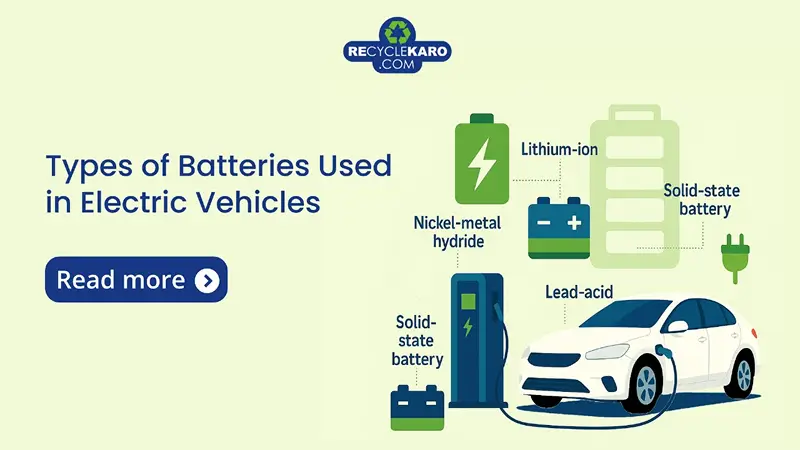

Types of Batteries Used in Electric Vehicles in India

Electric vehicles (EVs) are on the rise in India, thanks to increasing support for green transportation and government policies pushing for electric mobility. At the heart of an EV’s performance, safety and cost is the battery system. This blog will cover the various types of batteries powering EVs in India, their features, advantages, disadvantages and the future trends shaping this technology.

Overview of EV Batteries

The battery is the powerhouse of an electric vehicle, storing and supplying energy to the motor. The type of battery technology used affects the vehicle’s range, charging time, durability and efficiency. In India, the leading battery types are Lithium-ion chemistries, specifically Lithium Ferro Phosphate (LFP) and Nickel Manganese Cobalt (NMC).

Battery Types Used in EVs in India

Since lithium-ion (Li-ion) batteries come in various forms to suit different performance requirements, they have become the backbone of electric vehicle (EV) propulsion systems. Lithium-Nickel Cobalt Aluminum Oxide (NCA), Nickel Manganese Cobalt Oxide (NMC) and Lithium Iron Phosphate (LFP) are some of its variants. Every variant compromises between cost, power output and energy density which affects how well suited they are for different EV applications.

Lithium Ferro Phosphate (LFP) Batteries

LFP batteries are known for their safety and stability. They have a longer life cycle than NMC but lower energy density.

Advantages:

Eco-friendly: LFP batteries are more eco-friendly as they don’t use scarce and expensive metals like cobalt and nickel.

- Safety: LFP batteries are less prone to overheating and thermal runaway.

- Durability: They have a long life, can handle many charge cycles without significant capacity loss.

- Cost-Effective: LFP batteries are cheaper to produce due to abundant material.

- Eco-friendly: LFP batteries are more eco-friendly as they don’t use scarce and expensive metals like cobalt and nickel.

Disadvantages:

- Lower energy density: LFP batteries have lower energy density than NMC batteries, means they can store less energy in a given space. This results in lower range and performance for EVs.

- Higher weight: LFP batteries are heavier than NMC batteries, adds to the overall weight of the vehicle and reduces its efficiency.

- Lower voltage: LFP batteries have lower voltage than NMC batteries, means they require more cells to achieve the same power output. This increases the complexity and cost of the battery management system.

Applications in India: LFP batteries are used in budget friendly EVs and public transport due to cost benefits and safety. Companies like Tata Motors and Mahindra have adopted LFP technology in some of their models.

Nickel Manganese Cobalt (NMC) Batteries

NMC batteries provide higher energy density and power, suitable for wider range of applications. The composition can be adjusted by varying the nickel, manganese and cobalt ratio. Globally 60% of EVs sold now have NMC batteries.

Advantages:

- High Energy Density: NMC batteries are lighter and offer more range, better vehicle performance.

- Flexibility: Material ratios can be varied for different vehicle types.

- Smaller size: NMC batteries are smaller than LFP batteries, reduces the space and weight requirement for the electric vehicle.

- Higher voltage: NMC batteries have higher voltage than LFP batteries, means they require fewer cells to achieve the same power output. This simplifies the battery management system and reduces the cost.

Disadvantages:

- Shorter life span: NMC batteries have shorter life span than LFP batteries, degrades faster with each charge and discharge cycle. They last for 3 to 5 years depending on usage and maintenance.

- Narrow operational temperature: NMC batteries have narrower operating temperature band of 15°C to 35°C (59°F to 95°F) and are more prone to thermal runaway at high temperatures * Less eco-friendly: NMC batteries are less eco-friendly as they use scarce and expensive metals like cobalt and nickel which have high environmental and social impact.

Applications in India: NMC batteries are used in high performance and premium EV models like those from Hyundai and MG Motors where range and performance is the priority.

Emerging Battery Technologies

While LFP and NMC lead the current market, several new battery types are gaining attention:

Lithium Titanate (LTO): LTO batteries charge fast and last long but have lower energy density. They are suitable for applications that require frequent fast charging like public transport. Smartphone user who avoids fast charging and keeps their device at moderate temperatures can extend battery life by up to 25%, per Battery University. While these practices delay replacement, recycling remains inevitable.

Solid-State Batteries: Known for their potential to boost energy density and safety, solid-state batteries use solid electrolytes instead of liquids. Though still experimental, they have transformative potential for the EV industry.

Sodium–Ion Batteries: Sodium-ion batteries are gaining attention as sodium is cheaper and more abundant than lithium. Once developed further, they could be a cost effective solution.

Comparative Analysis of Battery Types

| Battery Type | Energy Density | Cycle Life | Safety | Cost | Applications |

|---|---|---|---|---|---|

| LFP | Low | High | High | Low | Affordable EVs, Public Transport |

| NMC | High | Moderate | Moderate | High | Premium EVs |

| Solid-State | Very High | Very High | Very High | TBD | Future EVs |

| Sodium-Ion | Moderate | Moderate | TBD | Low | Future applications |

| LTO | Low | High | High | Moderate | Fast charging applications |

Future Trends in EV Battery Technology

With India’s EV market growing rapidly, several trends will shape the future of battery technology:

Research into Alternative Chemistries: To address resource scarcity and environmental impact, research into alternatives like sodium-ion and solid-state batteries will gain momentum. These solutions could lead to more eco-friendly batteries that don’t use rare metals like cobalt.

Increased focus on Recycling: Under India’s Battery Waste Management Rules (BWMR) 2022, recycling is gaining momentum. Companies like LOHUM Cleantech are developing recycling technologies to recover valuable materials from used batteries and create a more sustainable ecosystem.

Advances in Battery Management Systems (BMS): Innovations in BMS are improving battery safety and efficiency by monitoring temperature and charge levels. This is critical in managing thermal runaway risk in high density batteries like NMC.

Government Policies and Incentives: The Indian government is promoting local manufacturing of battery components to reduce dependence on imports. Initiatives like Production Linked Incentives (PLI) are encouraging domestic production of lithium-ion cells and related components.

Conclusion

Battery technology is pivotal for the success of electric vehicles in India. While LFP and NMC currently dominate the market with their unique strengths, emerging technologies offer promising advancements for the future. As India embraces electric mobility, these developments in battery technology will support a more sustainable transport ecosystem, meeting diverse consumer needs and addressing environmental challenges.

With increased investment in research and development and government support, the future of EV battery technology in India is bright, poised to power the country’s electric vehicle for years to come.

You can find all the useful information you need on the Vavada mirror. Find out why players switch to the official Vavada website via the mirror, and discover the benefits: similar registration and login processes, bonuses, promo codes